TPED Officer statues

~2023~

Skills:

- 3D Printing - 3D Modeling -

- Wood Turning - Painting -

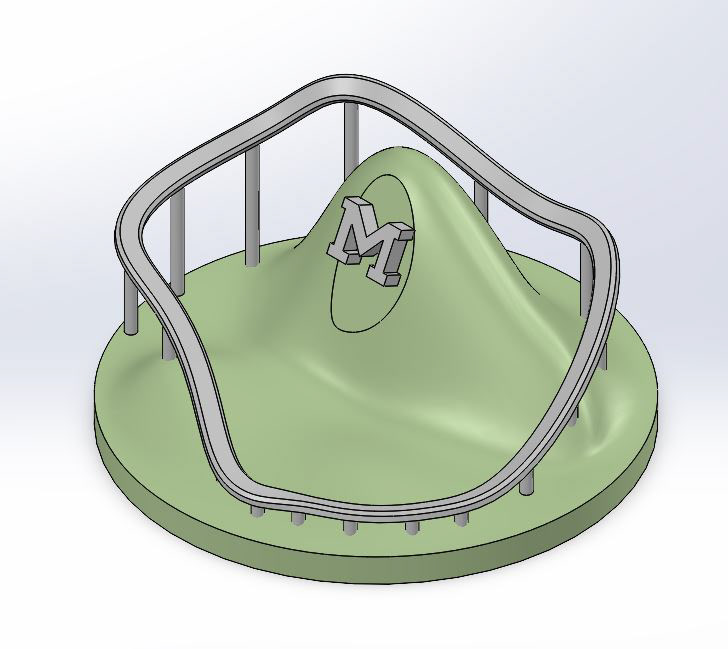

During my Senior year of college, I had the pleasure of helping found the Theme Park Engineering and Design Group at the Colorado School of Mines. The goal of the group is to expose students to the wonderful theme park industry at a typically aerospace-focused school. To thank the fellow founding officers for the experience as I graduated and moved onto a full-time engineering position, I made these statues for each of them.

The top was modeled in SolidWorks, which was interesting because it was my first attempt modeling an organic shape. I then printed them on my FDM printer and painted them to match the hill the School of Mines "M" sits on in Golden, Colorado. The bottom was turned out of cherry wood on my lathe, and the two were mated together using glue.

TPED Modeling workshop

~2023~

Skills:

- 3D Modeling -

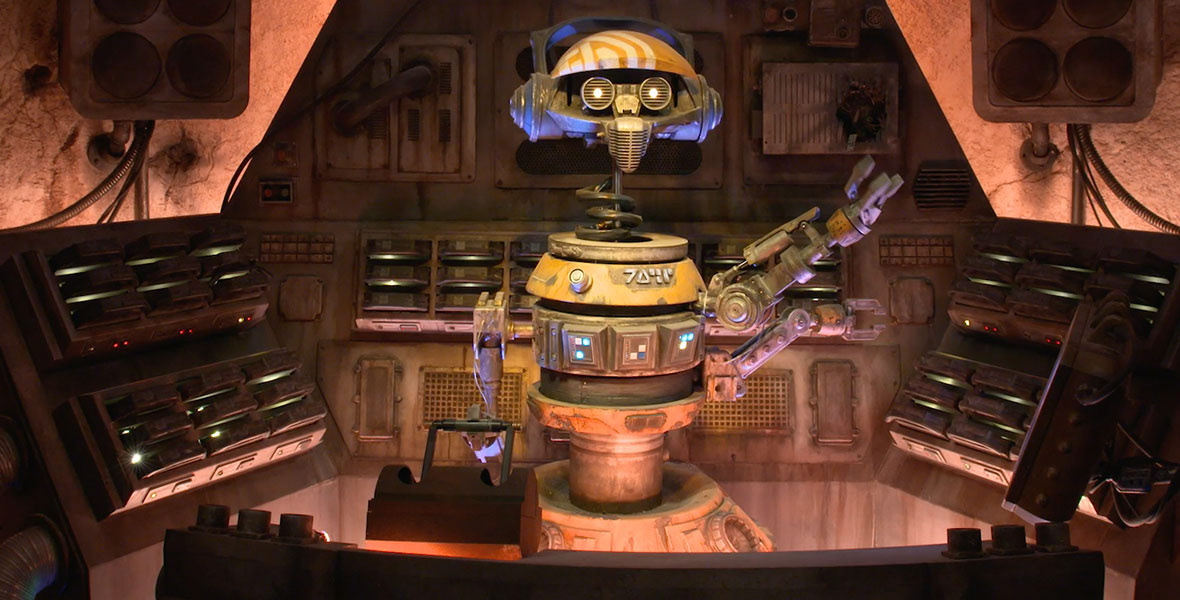

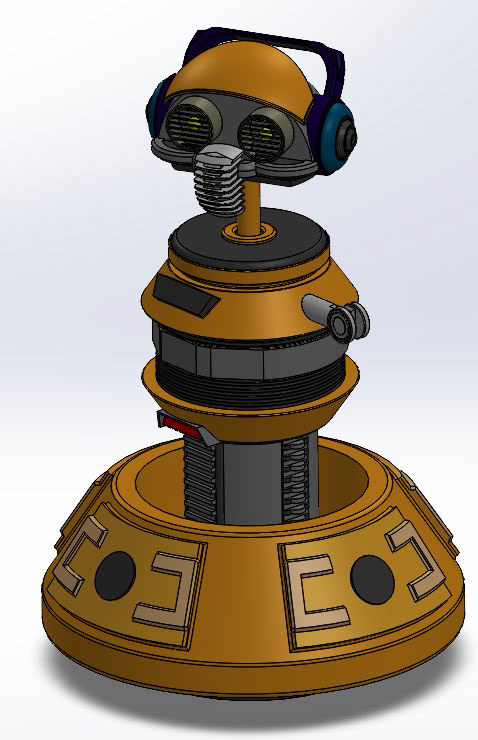

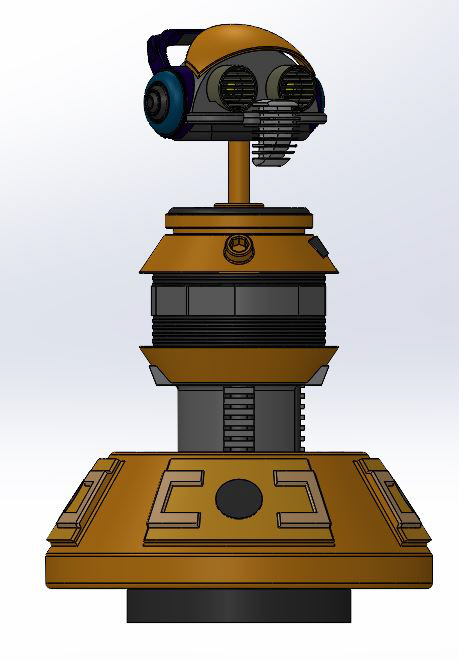

One of the responsibilities of the TPED Alumni Advisor is to host “workshops” for students to learn about different things they are passionate about. Through my work as a mechanical engineer, I have had the chance to spend hundreds of hours modeling on SolidWorks. Knowing that the curriculum at the school does not dive heavily into modeling, I chose to teach members more by guiding them through the creation of DJ-R3X, my favorite droid.

I modeled it using concepts that I found to be important and useful during the design process with the end goal of 3D printing kept in mind. I am currently working on a plan to make the model more concise and digestible, as I believe many features could be consolidated for teaching purposes.

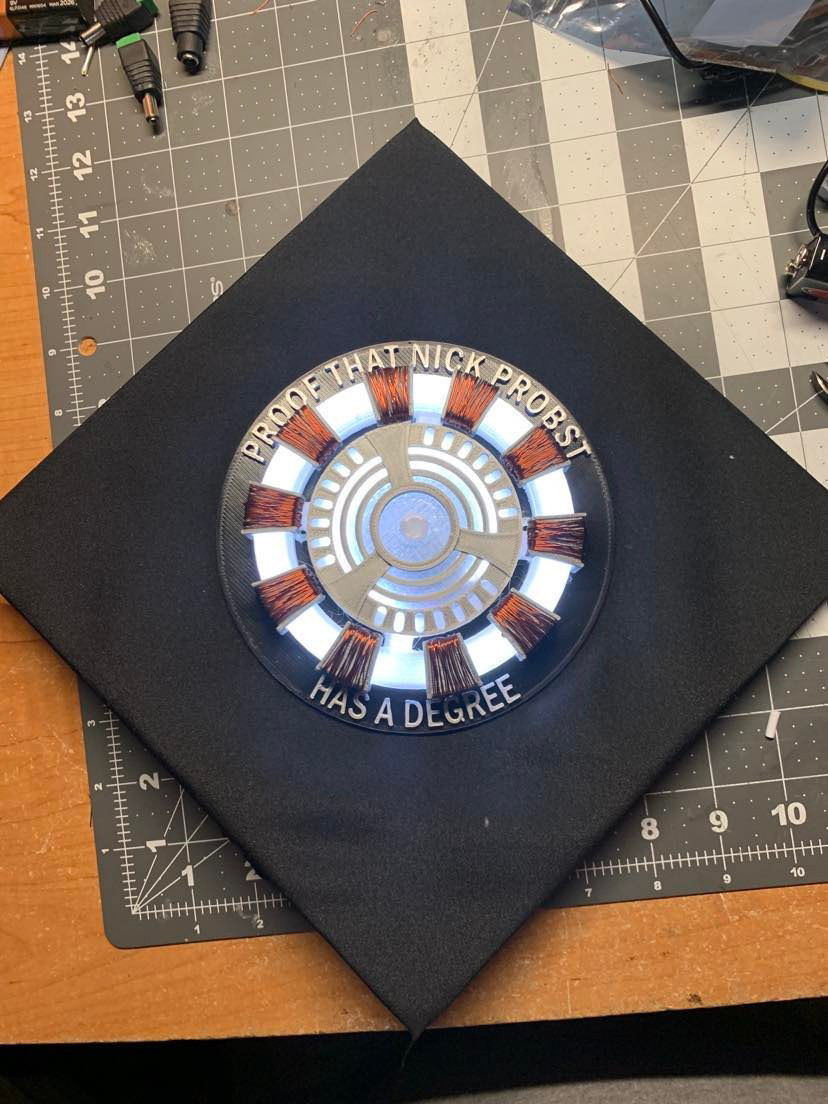

GRADUATION CAP

~2022~

Skills:

- 3D Printing - 3D Modeling -

- Basic Circuits - Painting -

For my college graduation, I decided to decorate my cap by replicating the original Arc Rector from Iron Man 1. Like many of my other projects, I 3D modeled the assembly in SolidWorks, making sure to have provisions for a LED strip and battery hidden in the cap.

I printed the light-up components in clear PETG to get the brightest results when powered. The rest of the assembly was printed in PLA and painted to look like metal. The "magnetic coils" were wrapped in copper wire and glued in place, giving the assembly more realism. This design made it quite easy for my family to find me during the ceremony.

LIGHTSABER CASE

~2022~

Skills:

- 3D Printing - 3D Modeling -

- Basic Circuits - Painting -

- Sewing -

During my most recent visit to Star Wars: Galaxy’s Edge I had the pleasure of building my own lightsaber in Savi’s Workshop. After the long journey home, I stored the saber in the corner of my closet in the case that I left Disney with. This didn’t seem like a proper fate for my lovely saber, so I decided to replicate the beautiful cases that the Legacy Lightsabers come with for myself.

I modeled everything in Solid Works and used hardware from McMaster Carr. I then printed it using my FDM printer and painted it. I pictured my lightsaber on a forest moon or Wookie-inhabited planet, so I chose to dirty it and paint it a darker green than the typical Legacy Lightsaber case. I also added lighting for an added effect.

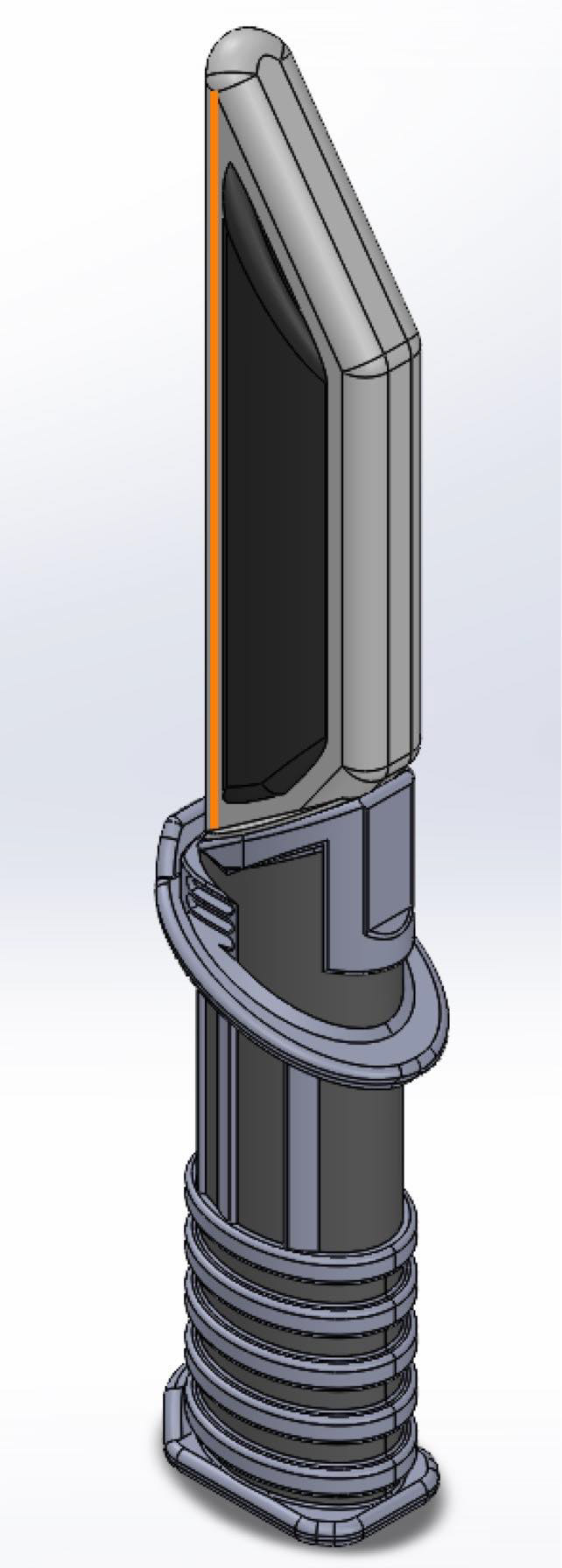

dark saber baby rattle

~2022~

Skills:

- 3D Printing - 3D Modeling -

One of my closest friends has a child due in October of 2022. I recently found myself in a heated discussion with this same friend about which lightsaber is the coolest. Results aside, the conversation was a ploy to see what lightsaber I’d be making for his son in the near future.

This Dark Saber was modeled in SolidWorks and printed using various filaments on my printer. I chose to avoid paint to keep it safe for a child. I also chose to print the blade itself with 0% infill, then added beads during printing to make it into a rattle. There were more pieces added to the sides of the blade to give it the Dark Saber glow and strengthen the blade.

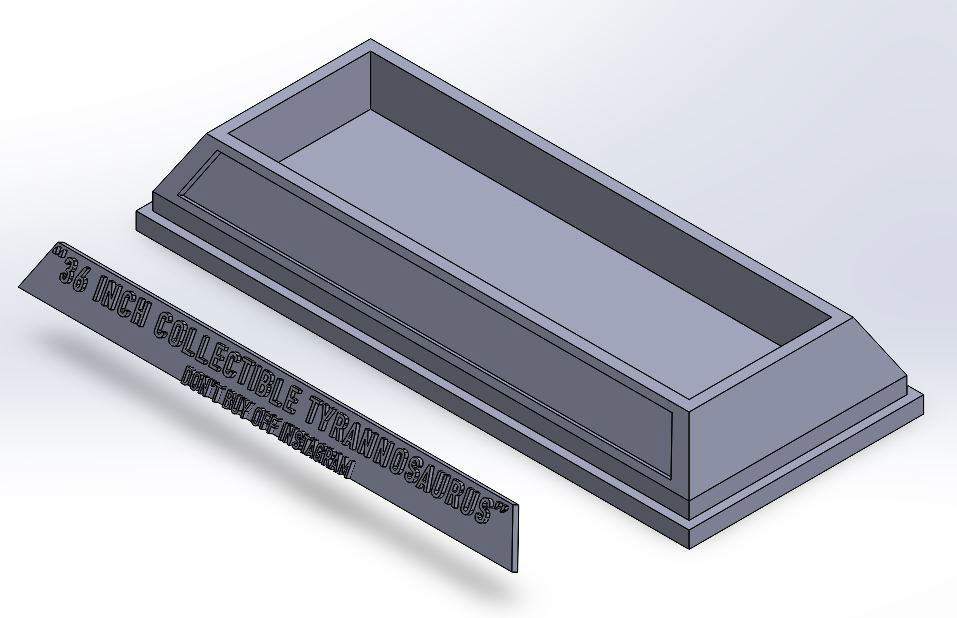

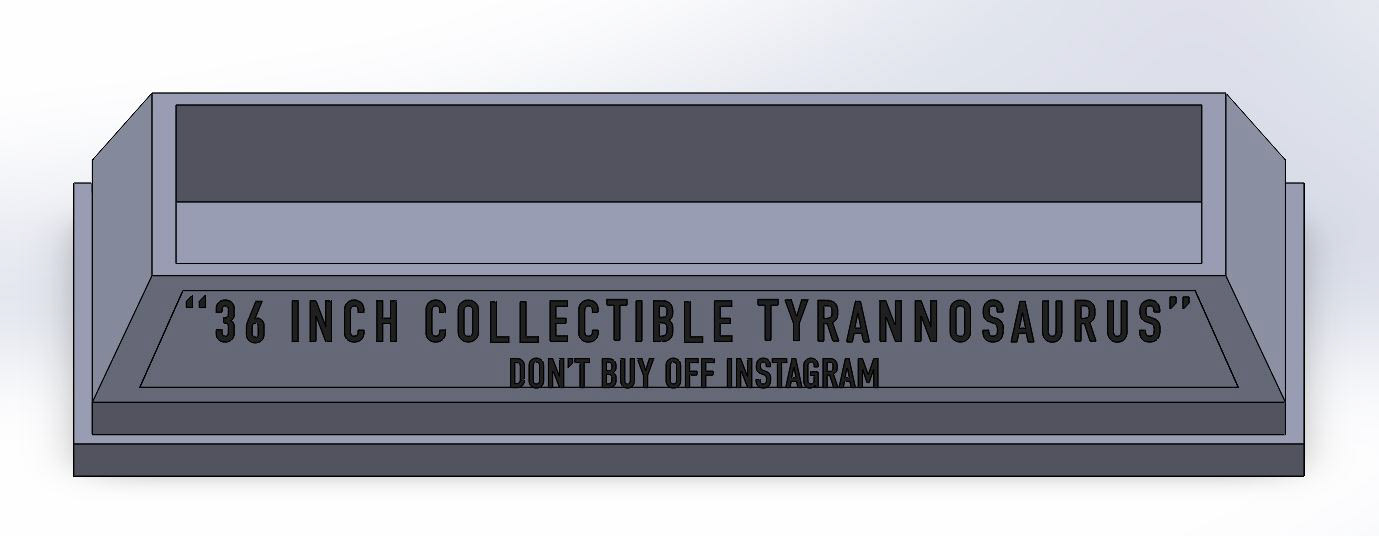

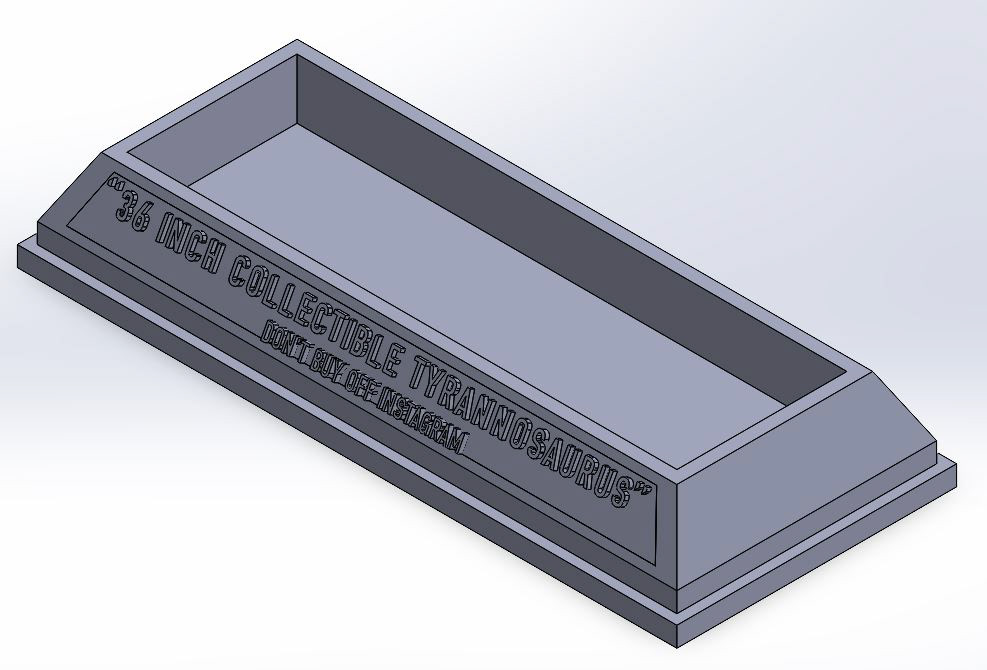

Tyrannosaurs museum display

~2022~

Skills:

- 3D Printing - 3D Modeling -

~2022~

Skills:

- 3D Printing - 3D Modeling -

A younger and naïve version of myself once found an advertisement on Instagram selling a “36-inch Collectible Tyrannosaurs”. The images in the ad were of a beautiful statue of the T-Rex from Jurassic Park towering next to a gentleman. The price was unbelievable, so I purchased one and waited eagerly. After a significant period of time, I still didn’t receive anything, so I started doing research.

I found out the pictures in the advertisement were the Sideshow Collectibles T-Rex and cost a lot more than I paid for. I chalked it up as a loss and figured I lost my money entirely. I then was delighted to get a 12-inch T-Rex with much less detail and lack of scenery around it.

This was when I decided to make a museum piece to show off my purchase in its full glory by modeling the base in SolidWorks and printing it on my FDM printer. I then attached a nice block of wood that has mounting provisions that connect to the feet of the T-Rex.